Our education and training services are designed to help Environmental Health and Safety departments and Shop Managers ensure they are doing all they can to reduce or eliminate employee risk while working with various types of equipment. Our talented team of machine operators, educators, writers, and illustrators can help you implement a top-notch training program for your facility.

Here are some of the steps we go through while completing a typical project:

| Define Documentation Scope: Which tools and machines require instructional documentation? What is the budget and time frame? How detailed should facility signage be? | |

Define Instruction Scope: Is the goal to have standardized classes, or informal sessions to work on specific skills or projects? For machine-specific training we have two training options that prove to be popular:

Training packages can also be a combination of the two options mentioned above. |

|

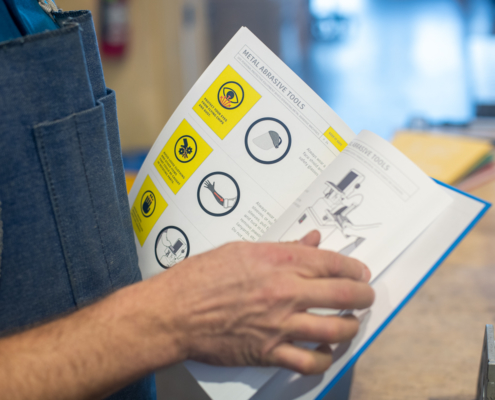

| Customize Documentation for Specific Needs: We work with your Risk Management team and Shop Manager to define shop policies and safety protocol. The content is designed to be clear and easy to read, with graphics that add clarity. | |

| Documentation Samples: APROE offers a core of educational documents that can be customized to fit your exact needs. A typical package includes a Shop Policy Document, Quick Start Guides, Student Assessments, and Instructor Guides to provide consistent instruction and signage. |

| Instructor Guide: This is a 5 to 10 page course outline that guides the instructor through the class, so that all class sessions, even if taught by different instructors, cover the same material. There is some flexibility for the instructor to tailor the class to more sophisticated students. |

|

| Quick Start Guide: This is a 5 to 20 page detailed handout, written for a student to use in class, to take notes, or as a reference at a later date. It typically includes safety hazards, text, images and detailed drawings of the tools and controls. Quick Start Guides can be laminated and bound and are typically left with the machine for future reference for returning students. |

|

| Student Assessment: A combination of a written test for the student and a checklist of skills the instructor should observe the student perform. |

|

| Shop Policy: This is a 1 to 2 page document that is crafted to outline your shop’s safety policies and guidelines. It typically is handed out during a Shop Orientation training session to employees and can be displayed as an in-shop poster. | |

| Signage: Charts, posters and machine-specific signs, which all remind students of basic safe machine operation and facility policies. |