Here are some guidelines for ensuring that the file you send us is able to be successfully processed by our system.

For 3-Axis Cutting

- Your file must be in DXF format and consist of shapes that are fully enclosed with no branches or cross over points (essentially “extrudable” as a shape). The parts are analyzed in the software as “islands” from the outside inward. Fully enclosed shapes are critical for our software to determine which side of the line to cut on.

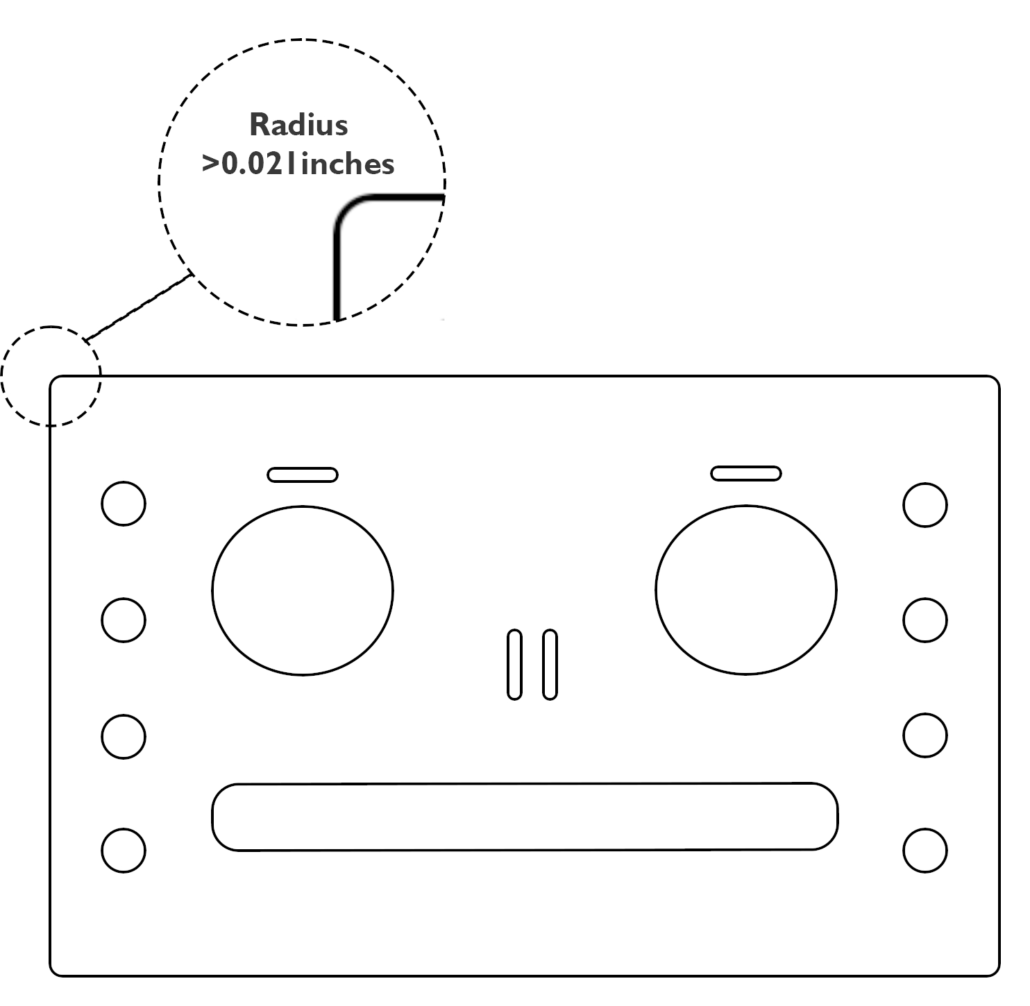

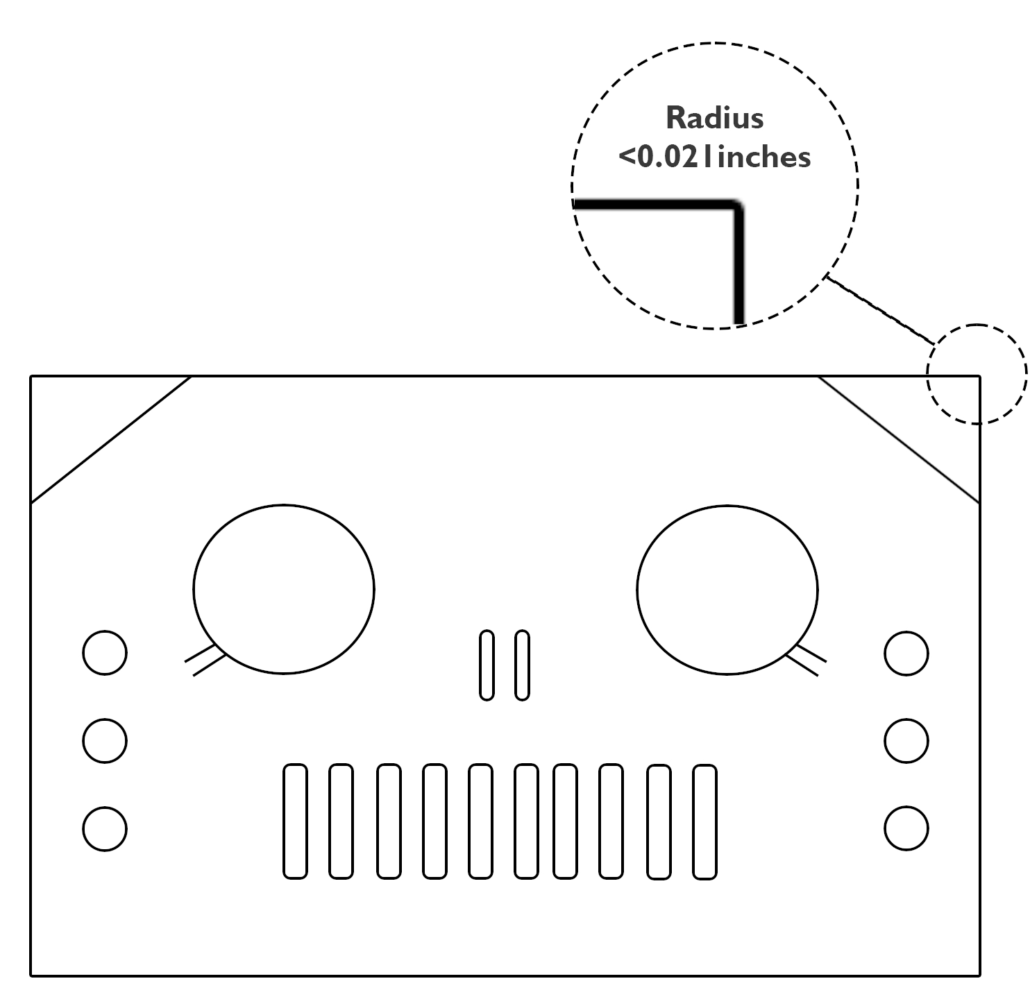

YES! NO! - The shapes in your file cannot have a radius smaller than 0.021 inches. Square corners can be resolved in our software with no problems, but cut parts with square internal corners will have a 0.021 inch radius.

- The shapes in your files must be organized by material and thickness (example: all parts to be cut in ¼” steel must be in the same file and all parts to be cut in ⅛” aluminum must be in a separate file).

- A standard sheet of material is 48” x 96” in length and width. Please see our FAQ for questions regarding the maximum part sizes our machine can handle.

For 5-Axis Cutting

- Your file must be a solid body exported in STEP format (ISO 10303-21, extension .stp or .step) and not include any angles greater than 60 degrees from the horizontal. There are quite a few shape possibilities that could prevent your part from being cut on our machine. Our operators will have to review your file and verify that we’re able to accommodate your request.

- The shapes in your file cannot have a radius smaller than 0.021 inches

- The shapes in your files must be separated by material and thickness (example: all parts to be cut in ¼” steel must be in the same file and all parts to be cut in ⅛” aluminum must be in a separate file). The required amount of space between your parts and material edges will depend on material thickness and cutting angles. Please send your files over for us to review and we will discuss material size requirements with you.The maximum cutting envelope for 5-axis cutting is 46” x 94”.

Part Nesting

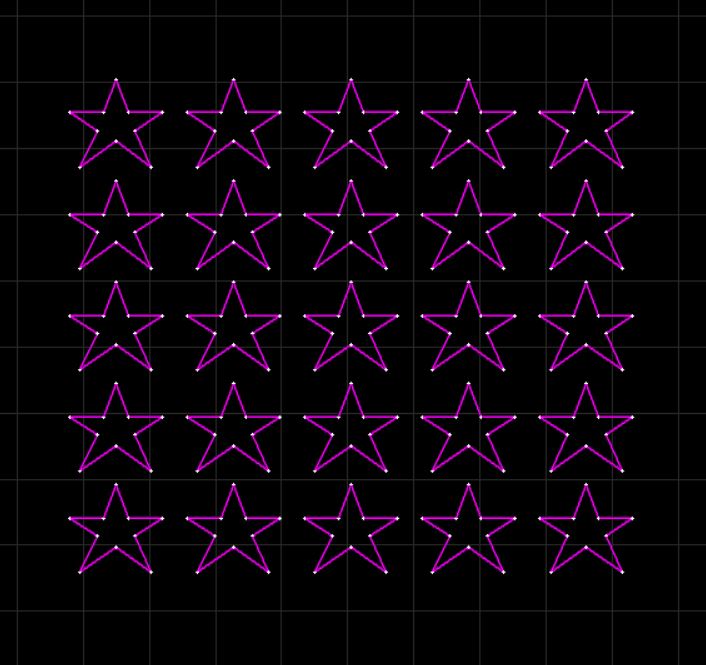

- If you need multiple parts cut, we can nest them for you on a sheet, or you can submit a file with parts that you have nested yourself using the below spacing and size requirements.

- Nesting parts will allow you to save money on material costs and reduce the overall quote for your order.

- Parts nested in a single file will all be cut on the same piece of stock material on our machine.

- All shapes must have a minimum of ⅜” of space between the other parts and the edges of the material. A standard sheet of material is 48” x 96” in length and width. Please see our FAQ for questions regarding the maximum part sizes our machine can handle.

- Files that follow these guidelines should be able to be successfully submitted to our automatic estimator and paid for online.